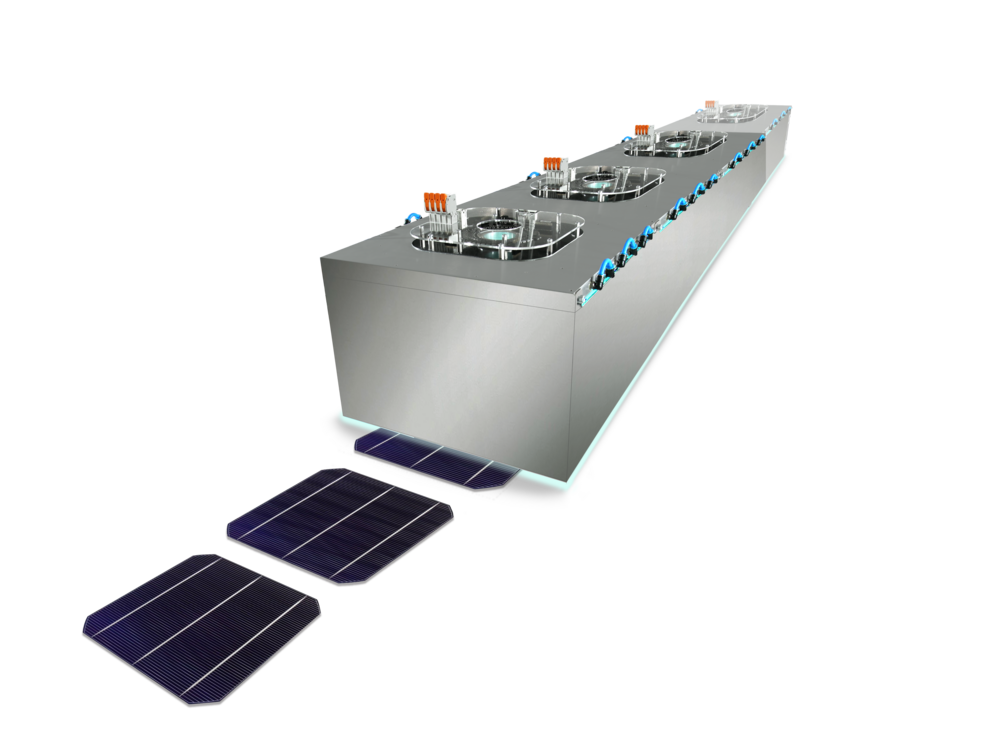

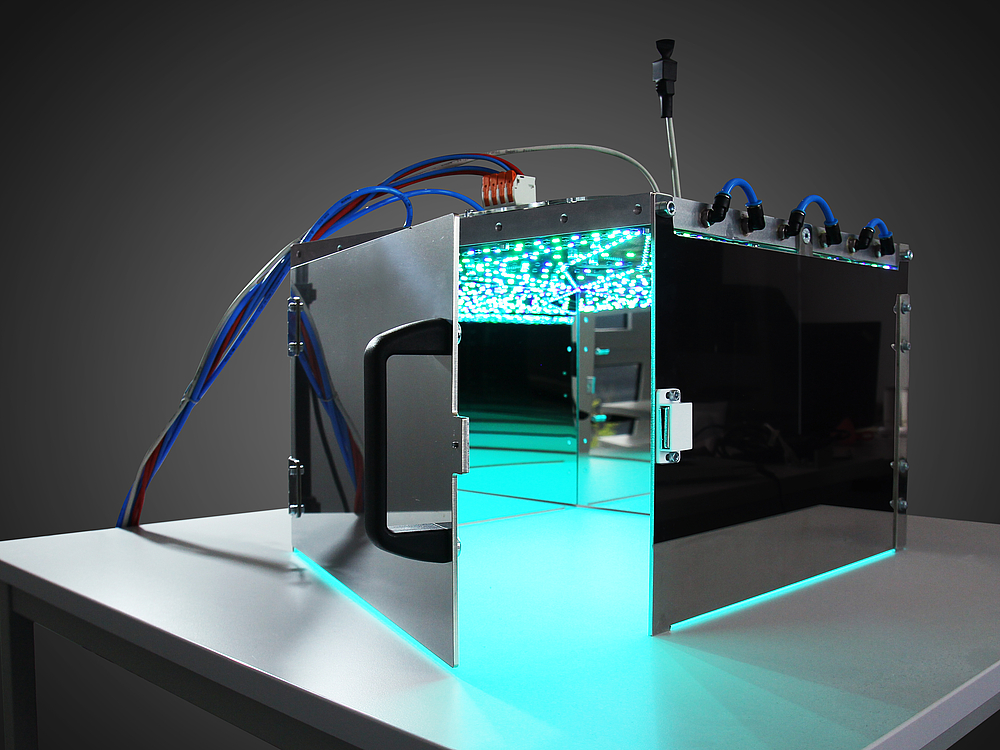

MBJ Light Soaking Unit

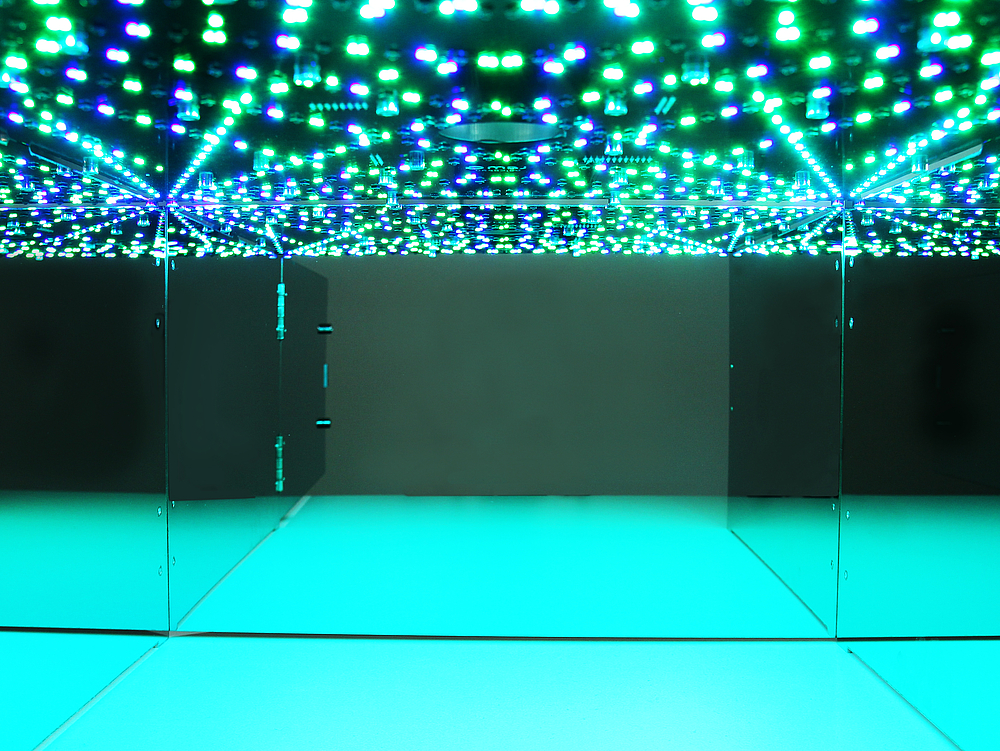

The MBJ Light Soaking Unit is designed for the development of new cell technologies such as perovskites. The basis is a 380x380mm LED unit with two separately controllable channels (blue/green and IR). The LED units are designed for continuous operation. Cooling units are required for continuous operation. Each LED channel delivers 1000W/m² at approx. 50% of the permissible current. This design achieves a service life of > 50,000 hours. The units can be used individually as a test bench for aging tests for solar cells or arranged in series for preconditioning in cell production before I/V measurements.